2025

- Renewed IATF 16949 Certification

- ISO 14001 Certificated

- ISO 45001 Certificated

2024

- ISO 14064-1 Certificated

2022

- Renewed IATF 16949 Certification

- Obtained the Green Factory

- Obtained the Cleaner Production

2021

- Received the Carbon Footprint Label

2019

- Renewed IATF 16949 Certification

- Acquired ISO 50001 Certification

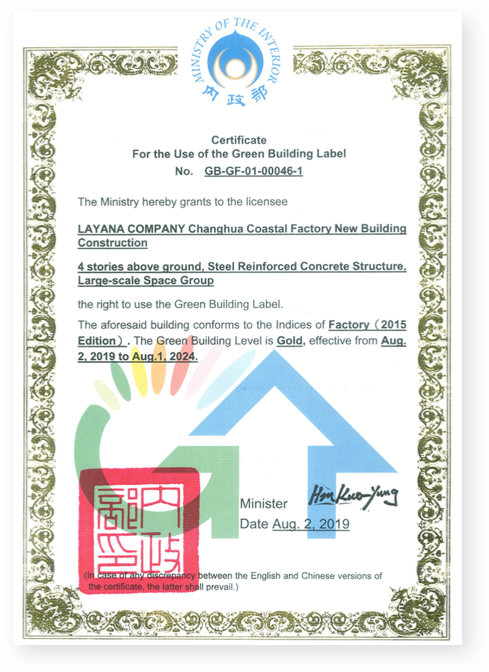

- Awarded Green Building Certification

2018

- Layana moved into its new headquarters

- Expanded into EV Industry

- Joined the supply chain of a global top 3 EV manufacturer

2016

- ISO 14001 Certificated

2012

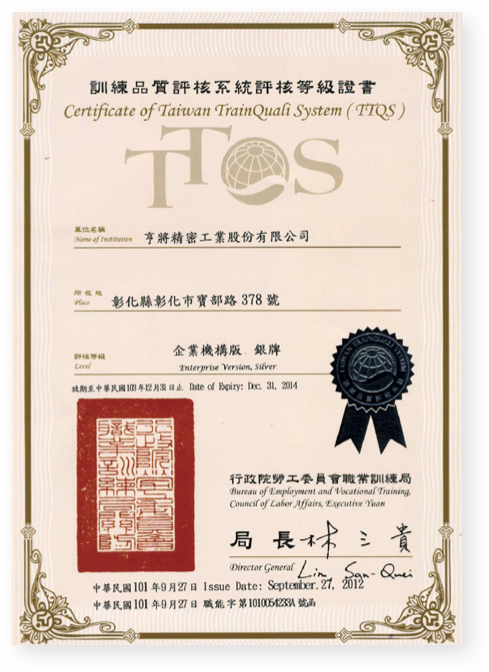

- Awarded TTQS Silver Medal from Council of Labor Affairs

2010

- The New Office Opened in China

2008

- Expanded to Off-road Truck & Aerospace Industry

2006

- ISO9001 Certified to Flatware Series

2005

- ISO/TS 16949:2002 Certified

2003

- Held 1st Six Sigma Project Presentation in Public

2002

- Started ISO/TS 16949:2002 training

2001

- ISO/QS9000:1998 Certified

- Developed Plastic Injection Techniques

2000

- Expanded to Automotive Industry

1999

- Expanded to Electronics Industry

1998

- ISO9001 Certified

1996

- ISO9002 Certified

1991

- Purchased Cutlery Production Line

1985

- Renamed to LAYANA Company

1984

- Started to Provide Progressive Die Stamping Service

1983

- Evolved Tooling Design Capability

1982

- Established the Tooling Design Company

|

Early Operations

In the year of 1982, the founder armed with only a small seed capital of NTD$ 200,000 and a vision, the founder embarked on a journey to start a business in a humble warehouse, utilizing his own garage at his home. |

|

The First Expansion In 1990, the new factory, spanning 1800m2 across three levels was completed. A year later, the manufacturing and sales of stainless-steel cutlery began in various countries across Europe and America, including the United Kingdom, France, Germany, Australia, and the United States. |

|

Created A Reusable Cutlery Brand In 2000, Layana Cutlery was established and designed based on the cultural heritage of the Orient, including chopsticks and Western cutlery - forks, knives and spoons.

To promote the importance of using reusable cutlery instead of disposable cutlery, Layana was able to use existing techniques - stamping and plastic injection to produce different series of cutlery - portable chopsticks, child cutlery set, etc. |

|

Investment In China In 2010, Layana opened offices in Kunshan, Suzhou and Guangzhou respectively. Layana also formed a joint venture with a local mold and stamping factory in Suzhou in order to integrate the local supply chain. |

|

Acquired ISO14001 Environmental Management System To achieve better environmental management, obtaining ISO 14001 certification was one of Layana's top priorities in business planning. Layana achieved the certification in 2016. |

|

Successions in Family Business Starting in 2017, the second generation took over the responsibilities of running the business, and aimed at integrating its existing technology and engineering capabilities, providing customers with customized automatic production and inspection equipment.

As a one-stop service company for multiple processes, mold design, production, and inspection for assembled, stamped, and injected parts shall all be completed in the same factory. |

|

The New Era With continued growth, Layana moved into its new headquarters in September 2018, covering a total floor area of 12,630m2. The building's colors represent five elements of the earth: the sun, blue sky, clouds, plants, and soil. It was designed with environmental friendliness and energy conservation in mind. Meanwhile, Layana joins the supply chain of a global top 3 EV manufacturer. |

|

Moving Towards the Vision In 2019, Layana not only renewed the IATF 16949 Certification but obtained Green Building - Gold Level and ISO 50001 Energy Management System, merging the rules into the company culture. |

|

Obtained the Green Factory Layana, in 2022, achieved recognition as one of the world's first green factories under the Green Factory Certification System. This certification is only attainable by successfully meeting the requirements of the Green Building and Clean Production Assessment System. |

|

Obtained ISO 14064-1 certification In 2024, Layana obtained ISO 14064 Greenhouse Gases certification early in the year, measuring the organization's carbon emissions, with the ultimate goal of reducing and eliminating GHG emissions. |

Today, Layana Company is an IATF 16949 certificated manufacturer and advanced engineering solution provider. We can integrate multiple manufacturing processes under one roof - precision metal stamping and insert molding, with automation or assembly lines to produce parts and sub-modules. Our products are applied in EVs, energy, automotive, electronics, aerospace, and so on.

Our pride in precision stamping is making small and high-complexity metal parts in mass production, which is applied with various stamping techniques such as fine blanking, deep drawing, and microstamping. With four decades of experience in the tool and die-making field, progressive stamping is one of our strengths.

For plastic injection, we can produce high-precision modules from small to medium-large sizes. Our injection molding machines are between 35T~250T to support clients from prototype to product, especially when combined with metals such as lead frames. Bi-material integrated plastic science is our strength in this field.

Overall, we focus on being clients' backbones and reducing their risks in many aspects to the minimum. We aim to become the world’s largest and most advanced manufacturer of EVs, aerospace, and energy products.

Certifications

TTQS |

Green Building – Gold Level Green Building – Gold Level |

IATF 16949 Automotive Quality Management System |

Energy Management System |

ISO 14064-1 GHG Emissions/Removals |