What Is the Cleaner Production?

Recently, the urgent need to reduce the industry's carbon footprint led to the term cleaner production being on everyone's lips today. However, only a few companies integrate a comprehensive strategy to achieve cleaner production. Cleaner production refers to new procedures and technological solutions enabling new practices at all industrial production levels for environmentally sustainable manufacturing. Reducing or eliminating potentially harmful components, minimizing the emission of waste of any kind to the environment, and achieving the product by reducing the amount of energy, hydrological resources, or the needed input materials, will contribute to cleaner production within an environmentally sustainable company.

The Characteristics of the Cleaner Production

- Renew Equipment – Installing more efficient equipment to use a smaller amount of material or inputs and require less electricity, water, or other resource consumption.

- Improvements in the usage of material – Implement improvements or new technologies to take more advantage of the available materials, avoid waste, or replace polluting materials.

- Design innovation – Reduce the amount of material needed or design more durable products over time.

- Improvements in waste treatment – Reuse and recycle all excess material and treat, reduce, and even eliminate waste before released into the environment.

- The Substitution of Packaging and Labeling – Decrease the amount of plastic and use materials that are recycled or obtained from cleaner production.

- Source materials locally – Use inputs from local manufacturers and optimize the distribution chain by reducing the mileage needed for inputs to reach the factory and for manufactured products to reach the end customer.

- Improvements in production and maintenance tasks – Prevent future potential environmental damage.

Improvements in facilities – Protect the health of employees and reduce energy, water, or any other resource consumption.

Cleaner production is a comprehensive concept that integrates all company departments. For the correct implementation of a strategy for cleaner production, it is necessary to coordinate and involve all the teams and all the departments to find possible failures, inefficiencies, or opportunities, propose and analyze potential improvements, and implement and measure them. Furthermore, when designing the corporative policy regarding environmental sustainability, it is critical to emphasize the continued implementation of cleaner production plans. Continuous improvement is how a business can stay competitive.

The Benefits of the Cleaner Production

The benefits of applying a cleaner production program are multiple and can be classified into two groups: social & environmental benefits and corporate benefits.

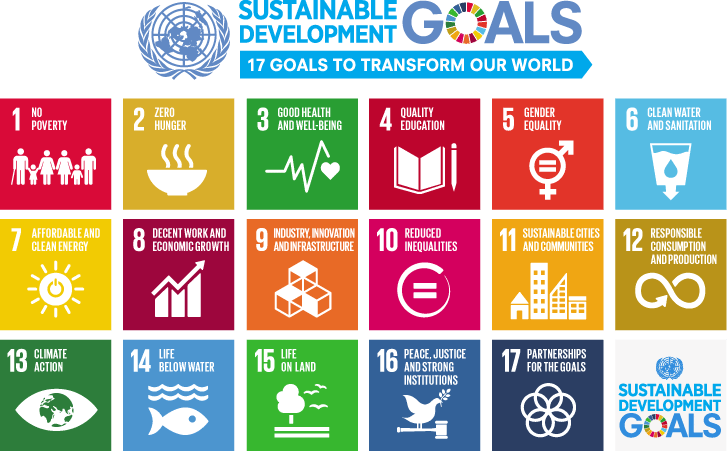

On the one hand, as mentioned in previous lines, companies continuously implementing an improvement program to achieve cleaner production proactively contribute to the collective achievement of a large part of the United Nations Department of Economic and Social Affairs' sustainable development goals. Through the implementation of cleaner production, we can contribute to the following achievements (UN official goal numbering in brackets):

- Good health and well-being (3) – A cleaner production site will be a much more pleasant and healthy environment (both physically and mentally) for employees. We can better prevent accidents at work, ensure that workers are healthy, and thus help relieve public health services.

- Clean water and sanitation (6) – Rainwater collection systems will help reduce water consumption, reducing demand and increasing clean water availability for those in need. Besides, for industrial water purification systems, a decent water purification and drainage system will ensure that the water after its industrial use can be recycled and reused.

- Affordable and clean energy (7) – By improving the energy efficiency of production equipment, the industrial demand for energy decreases, which will contribute to an energy price drop for households. In addition, increasing the demand for clean energy by incorporating it into industrial uses will boost renewable energy development, improving its technology and competitiveness.

- Decent work and economic growth (8) – Implementing a cleaner production program will help to improve the local business fabric resilience, preparing companies to be more competitive in the future and generating higher quality employment.

- Industry, innovation, and infrastructure (9) – The success of a cleaner production program is due in part to technological solutions or innovations in processes that make it possible to achieve more efficient use of available resources or reduce waste. The continuous search for these solutions will contribute to the development of collective ingenuity and the workers' preparation.

- Sustainable cities and communities (11) – A cleaner production is an inevitable step in turning a traditional factory into a green factory. Green factories help to create more sustainable, safe, and resilient cities.

- Responsible consumption and production (12) – Cleaner production is closely related to eco-efficiency since one of the ultimate goals is to reduce the carbon footprint when producing new goods. It is necessary to know how to convey to the customer the benefits of a cleaner production system so as not only to promote responsible production but also responsible consumption.

- Climate action (13), life below water (14) and life on land (15) – According to the European Environment Agency, industrial processes account for 9.1% of total greenhouse gas emissions, without counting the emissions emitted by the generation of energy necessary to feed factories. It is vitally important to reduce the carbon footprint when producing goods because the environmental consequences of rising temperatures can seriously jeopardize the fragile balance of ecosystems needed for the proper development of human and animal life. Melting ice from the polar caps, floods, droughts, devastating storms, or plagues are just some of the terrible consequences if the earth's average temperature keeps rising.

On the other hand, at a corporate level, the implementation of a cleaner production system has numerous advantages:

- Energy savings – Even though sometimes the installation of more energy-efficient equipment means higher installation or implementation costs, it will save on electricity bills in the long run.

- Water saving – Using water recycling systems means significant annual savings in water bills, apart from making the company more resilient to potential supply problems.

- Increase employees' efficiency – A clean environment, with clean air and adapted room temperature, stabilize employees’ health and work efficiency. In addition, many of the plans included in cleaner production programs bring measures that reduce the possibility of accidents at work.

- Improved company image – A company will have a better reputation and more prestige when it is concerned with reducing its carbon footprint and cares about taking care of its employees and members of the community where the company is based. It is also synonymous with transparency and commitment.

- Improved profit margins – Making better use of the material at the production time and reducing the amount of waste processed before emitting it into the environment will increase profit margins.

The Obstacles to the Implementation of the Cleaner Production

Although cleaner production systems bring numerous benefits overall, there are also concerns that lead some businesses to not prioritize clean production plans and instead postpone their implementation until national regulations compel them to make improvements. Some of these concerns include:

- Lack of funding for improvements - Implementing improvements sometimes requires a financial investment. In such cases, the motivation for investment and the potential long-term benefits of the improvements need to be carefully considered.

- Lack of cohesion - Implementing a clean production plan requires the full participation of all departments. It can be challenging to coordinate tasks and communicate effectively across different departments during the process.

- Lack of technological resources - Not all company departments can apply clean production system solutions at the same pace. However, companies should approach clean production with the same determination and commitment.

- Lack of environmental awareness - Not all companies consider environmental conservation as a core value and a guiding objective. Layana, on the other hand, not only recognizes sustainable development as an imperative goal but also believes that continuous improvement will consistently reduce carbon footprint and protect the environment.

The Exampple of Implementing the Cleaner Production

For instance, Layana's implementation of cleaner production encompasses a series of plans and measures categorized into three main areas: production and manufacturing, environmental design, and green management and social responsibility. These three categories not only harness the collective efforts of various departments but also demonstrate innovation in seeking solutions, which serves as the fourth criterion for evaluation. As a result, in 2022, Layana was awarded the Clean Production System Assessment Certificate. This certification validates the company's commitment to enhancing ecological efficiency and product yield while diligently reducing waste and minimizing adverse impacts on the environment and human health.

(1) Production and Manufacturing

This plan consolidates all the improvement measures implemented at Layana to reduce energy consumption, lower production costs, and enhance the working environment. Within these improvement measures, the following projects are included:

Energy Saving

- Implementation of automated warehousing: This measure reduces energy consumption and the emission of gases and other pollutants (as we require fewer warehouse equipment and space). Furthermore, compared to traditional warehouses, the installation of automated warehousing alleviates physical burdens on employees and reduces the probability of industrial safety accidents.

- Installation of LED lighting throughout the entire factory: Replacing traditional light tubes with energy-efficient LED lights not only contributes to energy savings but also enhances illumination.

- Deployment of heat recovery systems: By installing insulation materials in various factory equipment and heat recovery systems, we reduce energy consumption and maintain a conducive temperature within the factory.

- Adoption of alternative molds for material conservation: Through the use of substitute molds, our technical team significantly reduces material waste and manufacturing costs.

Investment in variable frequency air compressors: By phasing out fixed-frequency air compressors and adopting variable frequency ones, we greatly contribute to substantial electricity savings and reduced energy consumption.

Water Conservation

This program comprises two primary objectives: the reduction of water loss and the establishment of a system for rainwater collection.

- By installing sediment cooling towers to replace traditional water towers, we can minimize water loss (evaporation and splashing losses) and decrease water and energy consumption as well as production costs.

- The implementation of a rainwater harvesting system facilitates significant water conservation. Additionally, it equips Layana with the capability to respond to natural disasters, ensuring acute water shortages can be alleviated in the event of water supply issues such as droughts or malfunctions.

(2) Environmental Design

Environmental design refers to the innovative approach of focusing on the impacts on human health, chemicals, and the environment and economy during the design and manufacturing of commercial products and processes, rather than being solely driven by regulatory inducements. For example, all the improvement measures implemented at Layana serve not only to enhance products but also to improve employees' working conditions and the environment, while contributing to environmental protection:

- Reduction of plastic usage: Substituting plastic materials used in product packaging with alternatives such as recyclable paper and biodegradable materials.

- Incorporation of carbon footprint labels in Naya's products: Examining the carbon emissions from raw material production to the manufacturing and transportation processes, providing transparency for consumers to choose low-carbon products.

(3) Green Management and Social Responsibility

- Layana engages in various sustainable activities across different domains to contribute to the welfare of society, employees, and surrounding communities. Regular seminars on public welfare and environmental protection are organized by Layana. Furthermore, through the sponsorship of films screened at the 4K3D Dolby Cinema, we promote environmental awareness and highlight the impact of climate change on the natural environment, advocating for a low-carbon/low-energy lifestyle.

- Layana also believes in creating a green working environment to enhance employee health and safety, and encourages a green movement where everyone contributes to environmental conservation. Within the factory, Layana's colleagues utilize eco-friendly utensils, practice paperless office operations, and continuously recycle stationery materials.

Taiwan's Cleaner Production Assessment System

In alignment with the international environmental trends, the Taiwanese government encourages energy conservation and carbon reduction in our country's industries. In 2012, they established the Green Factory Labeling System. The qualification for the Green Factory Label requires compliance with both hardware and software aspects of green specifications. On the hardware side, the factory buildings must obtain the Ministry of the Interior's Green Building Label. On the software side, production and operational management must pass the Industrial Development Bureau's Clean Production Assessment. The Clean Production Assessment System is one of the qualifications for the Green Factory Label, and it is divided into the "General Industry Clean Production Assessment System" and the "Specific Industry Clean Production Assessment System."

Layana's factory falls under the category of the General Industry Clean Production Assessment System, and it successfully passed the Clean Production Assessment System in 2022.

Summary

The implementation of cleaner production enables factories to meticulously scrutinize the possibilities of waste reduction, recycling feasibility, and opportunities for energy conservation and carbon emission reduction within the working environment. This not only allows enterprises to minimize their environmental impact during the manufacturing process but also empowers each individual engaged in cleaner production to contribute to tangible, environmentally conscious actions.

Since 2016, through the collective efforts of all departments and employees at Layana, we have steadily achieved significant milestones in the Green Building and obtained the Clean Production System Assessment, making us the pioneering green factory in Changhua County. By embracing cleaner production, Layana has transformed itself into a more comprehensive and environmentally sustainable enterprise, encompassing aspects ranging from building structures to implementing office stationery recycling. Moving forward, we shall further endeavor to reduce our carbon footprint in accordance with current manufacturing emissions. After all, there can never be too many benevolent actions that humanity can undertake for the betterment of the environment.