The Definition of IATF 16949

IATF 16949 is a globally recognized quality management system standard specifically designed for the automotive industry. Its primary focus is on promoting continuous improvement and preventing waste and errors in the supply chain. Many automotive manufacturers worldwide have adopted IATF 16949 as their preferred global sourcing standard for automotive components, ensuring high-quality products and services that meet customer requirements and comply with legal and regulatory standards.

The Origin of IATF 16949

The origin of IATF 16949 comes from many car manufacturers establishing standard quality management systems according to their local national standards, regulations and requirements. To ensure global consistency and fairness, ISO/TS 16949 was first established and was one of the most widely used international standards in the automotive industry. It was later replaced by IATF 16949 in 2016, which redefined the quality management requirements for the automotive industry. The aim is to prevent product and service deficiencies and reduce errors and waste in the supply chain. It sets quality standards for direct suppliers who produce materials, products, service components or end services, such as heat treatment and electroplating processing.

Advantages of IATF 16949 Certification

-

Improved competitiveness:Obtaining the international standard certification of IATF 16949 helps companies gain customer trust and access to more business opportunities, thus enhancing their competitiveness.

-

Increased business value:The spirit of IATF 16949 is continuous improvement, which can increase business value and ensure sustainable company operations.

-

Prevention of product deficiencies:Following the quality management process of IATF 16949 can reduce nonconforming products and minimize internal and external failure costs.

-

Increased efficiency:Following the IATF 16949 system architecture can improve product quality and increase profitability and efficiency through appropriate management.

-

Quality assurance:Establishing 1st to 3rd-level documents and using procedural manuals to cycle through the company's overall operations in accordance with the IATF 16949 system architecture helps to increase customer satisfaction by ensuring strict quality control.

The Five Core Tools in IATF 16949

To ensure consistency and strengthen collaboration in the automotive industry supply chain, IATF 16949 provides five core tools to link quality operations in product design, process design, production, installation, and service. The five core tools are:

- APQP ─ Advanced Product Quality Planning: A structured method used to identify and establish the steps necessary to ensure customer satisfaction with a product.

- PFMEA ─ Process Failure Mode and Effects Analysis: A systematic review and analysis of new/revised processes to anticipate, address, or monitor potential process issues for new/revised product projects.

- MSA ─ Measurement System Analysis: A process used to evaluate measurement units or assess measured characteristics using a set of instruments or gauges, standards, operations, methods, fixtures, software, personnel, environment, and assumptions; in other words, the entire process used to obtain measurement results.

- PPAP ─ Production Part Approval Process: A process used to determine if a supplier has understood all of the customer's engineering design records and specifications.

- SPC ─ Statistical Process Control: The use of statistical techniques, such as control charts, to analyze a process or its output, in order to take appropriate action to achieve and maintain a state of statistical control and improve process capability.

The Conditions for Obtaining IATF 16949

To understand the path to certification, it is crucial to comprehend both the conditions required for obtaining IATF 16949 certification and the steps involved in its implementation.

- Implementation of ISO 9001: Your organization needs to first implement ISO 9001 since IATF 16949 is built upon ISO 9001, with specific automotive industry requirements added. Ensure that your organization is already ISO 9001 certified.

- Quality Management System: You must establish and maintain a quality management system to ensure compliance with all requirements of the IATF 16949 standard.

- Process Analysis and Improvement: Conduct an analysis of various processes to identify potential improvement opportunities and take measures to reduce variability and enhance efficiency.

- Supply Chain Management: IATF 16949 places high demands on the supply chain. Ensure that your suppliers also comply with the relevant quality standards.

- Measurement and Analysis: Develop effective measurement and analysis processes to monitor and improve product and process performance.

- Document Control: Implement a document control process, including document version control, document reviews, and approvals.

- Risk Management: Perform a risk assessment to identify potential risks that could lead to issues and take steps to mitigate these risks.

Steps to Implement IATF 16949:

To ensure effective implementation and achieve IATF 16949 certification, it is crucial to follow a series of strategic and methodical steps.

- Understanding the IATF 16949 Standard: Your team must gain a comprehensive understanding of the requirements of the IATF 16949 standard to ensure your organization meets these requirements.

- Planning: Develop a project plan that includes resource allocation, setting a timeline, and defining tasks.

- Team Organization: Assemble a team dedicated to IATF 16949 certification, ensuring team members possess relevant knowledge and experience.

- Internal Audits: Conduct internal audits to determine if your organization complies with IATF 16949 requirements. Identify potential issues and take corrective actions.

- Employee Training: Ensure your employees understand the IATF 16949 standard and can effectively execute related tasks.

- Document Preparation: Ensure your quality management system documents meet the requirements of the IATF 16949 standard.

- External Audit: Contract a third-party auditing agency certified in IATF to perform an external audit. They will evaluate your organization's compliance with the standard.

- Corrective Actions: If issues are identified during the external audit, take corrective actions to resolve these issues.

- Certification Attainment: If your organization successfully passes the external audit, you will obtain IATF 16949 certification.

- Maintenance of Certification: Regularly conduct internal audits and maintain the quality management system to ensure ongoing compliance with the IATF 16949 standard.

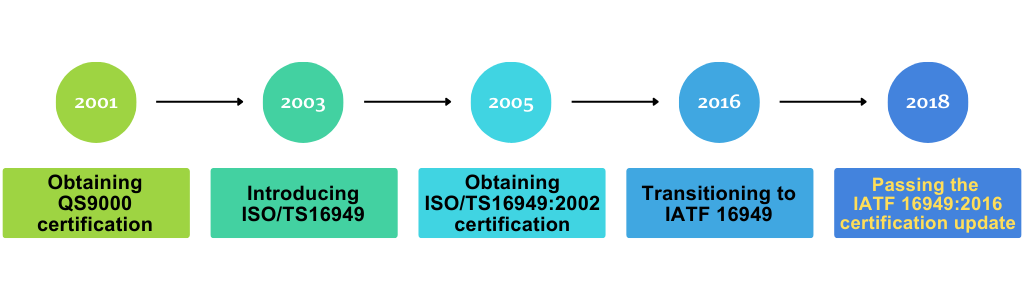

History of IATF16949 Compliance at Layana

Layana is an integrated automated manufacturing factory that has been implementing IATF 16949 for over 20 years. In 2001,Layana obtained QS9000 certification and started implementing ISO/TS 16949 in 2003, obtaining ISO/TS16949:2002 certification in 2005. To this day, LAYANA has continuously used IATF 16949, having converted to it in 2016. When the Lukang headquarters was completed in 2018, the IATF 16949:2016 certification was also successfully obtained.

| IATF 16949 Product Quality System Update - Supplementary Course | IATF 16949 Product Quality System Update - Internal Audit | IATF 16949:2016 Quality Training |

Conclusion

Only high standards of quality certification and inspection can create the best product quality.

For the past 41 years, LAYANA has focused on manufacturing technologies such as metal stamping, plastic injection, plastic over-molding, and automated production. The company has always implemented its quality management system in accordance with the international standard of IATF 16949, and uses a scientifically-guided management approach to fulfill its quality commitments to customers. The company slogan " TQM comes from good working attitude and character " is deeply rooted in Layana's DNA.

Read more about quality

Six Sigma