ESG

Layana Company - ISO 14001 Certified Company for Sustainable Manufacturing Excellence

Layana Company stands out as a trailblazer in its industry for ESG implementation. As one of the first companies in Changhua to achieve the Green Factory standard, Layana has also earned ISO 14001 certification—an internationally recognized benchmark for Environmental Management Systems (EMS). This achievement highlights Layana’s steadfast dedication to environmental sustainability, continuous improvement, and operational excellence across its manufacturing processes. With the ISO 14001 certification, Layana reinforces its position as an eco-conscious production partner, committed to reducing environmental impact while maintaining exceptional product quality. Business customers and stakeholders can trust in partnering with a certified, environmentally responsible manufacturer that adheres to global best practices in sustainable production.

ISO 14001: A Foundation for Environmental Management

ISO 14001 is a globally accepted standard for designing and implementing a robust environmental management system. It equips organizations with a clear, structured framework to identify, manage, monitor, and address their environmental responsibilities. By securing ISO 14001 certification, Layana demonstrates that its environmental management processes align with stringent international benchmarks, ensuring a systematic approach to minimizing its ecological footprint while adhering to regulatory requirements. Central to ISO 14001 is the plan-do-check-act (PDCA) cycle, which embeds a culture of continuous improvement in environmental practices. For Layana, this means consistently evaluating and refining its sustainability initiatives to meet rising standards and exceed stakeholder expectations.

Commitment to Sustainable Manufacturing and Green Initiatives

Through focused initiatives, Layana slashes waste, conserves energy, and curbs pollution—leveraging energy-efficient innovations like LED lighting and heat recovery systems while streamlining production to minimize scrap and emissions. These efforts dovetail seamlessly with broader programs, such as its Cleaner Production initiative and Green Factory status, as well as Green Building Certification for its main facility, reflecting a holistic dedication to eco-conscious manufacturing. By embedding practices like carbon footprint monitoring, recycling, and water collection system, Layana achieves growth without compromising the planet. These measures not only fulfill ISO 14001 requirements but also enhance efficiency and operational excellence. Layana’s environmental team relentlessly pursues ambitious targets and measures progress, demonstrating that sustainability and business success are intertwined—an approach further strengthened by additional certifications like ISO 45001 for occupational health and safety and ISO 14064 Greenhouse Gases, solidifying Layana’s leadership in responsible innovation.

What Are the Benefits of Getting an ISO 14001 Certification?

- Enhanced Brand & Market Edge: Sourcing from a certified green leader boosts clients’ eco-friendly reputation, attracting sustainability-focused consumers and opening new markets—partners gain a competitive differentiator too.

- Lower Carbon Footprint: Products made with reduced energy and waste shrink clients’ environmental impact, aligning with their sustainability goals and supporting partners objectives.

- Sustainable Collaboration: Layana’s expertise in environmental best practices enables clients (and partners) to innovate on green solutions, fostering a resilient, responsible supply chain that benefits all stakeholders.

Partnering with Layana delivers clients reliability, cost advantages, and a stronger green profile, while empowering both clients and partners with a shared commitment to sustainability and market success.

|

Category |

ISO 14001-Certified Company (e.g., Layana) |

Conventional Company |

|---|---|---|

|

Regulatory Compliance & Risk Management |

- Fully complies with strict environmental regulations |

- Faces challenges meeting regulations |

|

Brand Strength & Market Position |

- Builds strong eco-conscious brand image |

- Limited appeal in green markets |

|

Environmental Impact |

- Lower carbon footprint through reduced energy use and waste |

- Greater environmental footprint |

|

Innovation & Sustainable Growth |

- Fosters innovation through green initiatives |

- Lacks focus on sustainable development |

Leading the Way to a Sustainable Future

Layana’s achievement of ISO 14001 certification is more than just a trophy on the wall – it’s a proactive promise to continuous improvement in sustainability and a brighter, greener future for all stakeholders involved. Layana will continue to build on this foundation, investing in innovative green initiatives, such as the carbon emission label implementation, and maintaining transparent environmental performance metrics to ensure it remains at the forefront of sustainable manufacturing.

ISO 45001 Occupational Health & Safety Management System

Layana Company is ISO 45001 certified, marking a significant milestone in its commitment to occupational health and safety. As a globally approved supplier, Layana demonstrates that the well-being of its employees is paramount and integrated into every aspect of its operations. This certification means that Layana’s facilities and processes meet international standards for safe working conditions and risk management. For clients and partners, it translates into a trusted partnership with a manufacturer that prioritizes safety, reliability, and compliance – ensuring smoother operations and peace of mind.

Layana Company – ISO 45001 Certified for Workplace Safety Excellence

Layana Company is ISO 45001 certified, marking a significant milestone in its commitment to occupational health and safety. As a globally certified supplier, Layana demonstrates that the well-being of its employees is paramount and integrated into every aspect of its operations. This certification means that Layana’s facilities and processes meet the highest international standards for safe working conditions and risk management. For clients and partners, it translates into a trusted partnership with a manufacturer that prioritizes safety, reliability, and compliance – ensuring smoother operations and peace of mind.

ISO 45001 – A Systematic Approach to Health and Safety

ISO 45001 is the global standard for Occupational Health and Safety Management Systems, guiding companies to improve workplace safety. Released in 2018, it replaced the older OHSAS 18001 and is now the top standard worldwide. It pushes companies to spot hazards, assess risks, follow laws, and set up controls to prevent harm. It is not just about rules—it requires leaders to step up and employees to get involved, making safety a core part of the business.

ISO 45001 is recognized in over 179 countries and boasts nearly 400,000 certifications, demonstrating its widespread relevance across various industries. The standard operates on the straightforward Plan-Do-Check-Act (PDCA) cycle. For instance, a company like Layana applies it as follows: during the Plan phase, Layana identifies safety objectives and assesses potential risks. In the Do phase, the company implements safety protocols, trains employees, and mitigates hazards. The Check phase involves monitoring incidents, conducting safety audits, and ensuring compliance. Finally, in the Act phase, Layana’s leadership evaluates outcomes and drives continuous improvement. This cycle keeps safety efforts active and up-to-date, ensuring safe and compliant workplaces. ISO 45001’s straightforward, flexible system helps companies like Layana keep safety first.

Client and Partner Benefits of ISO 45001-Certified Manufacturing

When a manufacturer like Layana attains ISO 45001 certification, it not only improves internal safety but delivers significant value to clients and business partners. Here are the key benefits that Layana’s clients and partners gain from our status as an ISO 45001-certified supplier:

- Legal Compliance and Fewer Disruptions: Layana’s ISO 45001 certification ensures it follows safety laws, reducing the chance of accidents, penalties, or shutdowns. Clients get a steady supply with no delays from safety issues.

- Better Reputation and Responsibility: Layana’s focus on safety boosts its image as a responsible company. Clients benefit too, showing they choose ethical suppliers, which supports their ESG goals.

- Safer Collaboration and Less Risk: Layana’s certified safety measures make it a secure place for visitors like clients or auditors. This lowers accident risks and liability, making partnerships smoother and safer.

|

Aspect |

ISO 45001-Certified Company |

Conventional Company (No Formal OH&S System) |

|---|---|---|

|

Safety Management |

Structured and audited OH&S system with clear accountability. |

Ad-hoc safety practices with inconsistent application. |

|

Risk Identification |

Proactive risk assessments and preventive measures. |

Reactive responses to incidents; limited prevention efforts. |

|

Employee Involvement |

Active employee participation in safety initiatives. |

Top-down approach with minimal worker input. |

|

Regulatory Compliance |

Systematic and proactive legal compliance, often exceeding minimum requirements. |

Basic compliance with risk of falling behind on updates. |

|

Incident Management |

Thorough investigations with root cause analysis and corrective actions. |

Superficial handling of incidents; limited organizational learning. |

|

Continuous Improvement |

Ongoing safety enhancements through structured audits and reviews (PDCA cycle). |

Little to no formal improvement processes; changes only happen after major problems. |

Continuous Improvement in Health & Safety Performance

Achieving ISO 45001 is just the start for Layana—it is a commitment to ongoing improvement. We regularly monitor its health and safety performance, using internal audits and management reviews to assess progress toward safety goals. The key safety metrics, like injury rates and audit results, are tracked to measure progress and set higher targets. Following the PDCA cycle’s “Act” phase, Layana makes changes whenever necessary to ensure safety outcomes. This persistent effort ensures that, even with certification, Layana’s safety practices keep advancing, fostering a proactive safety culture focused on excellence, not complacency.

A Safer and Sustainable Vision with Layana

Layana’s ISO 45001 certification showcases its leadership in workplace safety and health, reflecting a strong commitment to employee protection and top-tier operational standards. Beyond quality manufacturing and timely delivery, this milestone assures customers of a safe, responsible supply chain.

In alignment with the philosophy and framework of ISO 45001, Layana has developed a comprehensive set of systems and protocols aimed at strengthening resilience against accidents or emergencies, positioning ourselves among the top preferred suppliers for reliability and performance. Several key measures distinguish us from less resilient competitors, including:

- Industrial-scale rainwater collection systems, designed as a contingency plan to mitigate risks and costs associated with water supply disruptions.

- Raft foundation engineering in our Green Factory Building, enhancing structural resilience and risk prevention in the event of earthquakes.

- Immediate response plans to labor shortages, maintaining operational continuity under workforce disruptions.

- Robust cybersecurity firewall systems, daily information offsite back up and excellence in information management, protecting sensitive data from cyber threats.

- Emergency response plans for supply chain or purchasing interruptions, complemented by regular training and drills to ensure readiness.

- Fully automated storage room reducing the labor accidents related with goods and materials handling operations.

These initiatives collectively reinforce Layana’s commitment to operational excellence and long-term partnership with clients. Safety is core to Layana’s identity, with a relentless push for zero accidents and ever-higher health and safety benchmarks. Partnering with Layana means choosing a future rooted in trust, reliability, and excellence across all facets of manufacturing.

Walk Taiwan Program

At Layana, we are deeply committed to the three pillars of ESG: environmental protection, pedestrian rights, and personal health

Quick Navigation

|

Layana firmly believes that environmental protection, social responsibility, and corporate governance (ESG) are the foundation for sustainable business development. We are committed to incorporating ESG principles into our daily operations and actively promoting environmental sustainability, social progress, and personal health in Taiwan through the "Walk Taiwan" project. This is achieved by awarding certificates to those who complete walking around Taiwan, encouraging everyone to accomplish this remarkable feat of over 1000 kilometers. |

Our Vision

Taiwan has a primary walking route around the island

1. Environmental Sustainability: Protecting Taiwan’s Natural TreasuresThe "Walk Taiwan" project encourages exploring the beauty of Taiwan in a low-carbon or even zero-carbon way, reducing the burden of tourism on the environment. We are dedicated to:

2. Social Responsibility: Advocating for Pedestrian RightsWe recognize that pedestrian rights are a key indicator of urban civilization, and therefore we actively promote:

3. Personal Health: Promoting Healthy Living for All AgesThe "Walk Taiwan" project is not only about exploring natural beauty, but also about promoting a healthy lifestyle for all ages. We are committed to:

|

Walking Certification Process

- Use a mobile GPS app to compile supporting documents.

- Fill out the itinerary form.

- After completing the island walk, fill out the application form.

For walks completed before January 1, 2027, GPS can be used for verification, and other supporting evidence may include but is not limited to the following:

-

Walking photos

-

Personal journals or reflections: Paper, electronic format, or online posts are all acceptable.

-

Video recordings

For more detailed information, please refer to the Walk Taiwan website’s Certification Process Section.

Walk Taiwan Sharing Sessions

Layana regularly organizes Walk Taiwan Sharing Sessions across Taiwan, where we invite those who have completed the walk around Taiwan (often referred to as "walkers") to share their unique stories. Although everyone embarks on their walk around Taiwan for different reasons, their love for this land is the same. Layana’s "Walk Taiwan" project not only promotes tourism but also serves as a model for practicing ESG principles. We will continue to promote this project, expand its impact, and join forces with more partners to contribute to Taiwan’s environmental sustainability, social progress, and personal health. We believe that through ongoing efforts and collaboration, the "Walk Taiwan" project will become an important milestone in Taiwan’s sustainable development, creating a better future for the island.

ISO 14064 Greenhouse Gas Verification

Layana Corporation Successfully Completes ISO 14064-1 Audit Certification

Layana has attained international standards in greenhouse gas inventory, enhancing the image of our factory. Through internal and external verification and certification, the accuracy and credibility of the inventory results are ensured.

For various greenhouse gas emission sources, we employ targeted methods for calculation:

- Stationary Combustion Sources: For example, the gas used in the kitchen, Layana utilizes the carbon emission coefficient method and mass balance method to calculate its greenhouse gas emissions.

- Moving Combustion Sources: Such as fuel combustion in transportation equipment, Layana uses the carbon emission coefficient method to calculate greenhouse gas emissions.

- Fugitive Emission Sources: For example, septic tanks; Layana's calculation involves the number of employees × annual working hours × carbon emission coefficient × GWP for septic tanks, and for refrigerant fugitive emissions, Layana estimates annual fugitive emissions based on original equipment fill quantity and annual fugitive rate.

- Externally Purchased Electricity: Calculated using the annual carbon emission coefficient announced by Taiwan Power Company.

- Emissions from Solid and Liquid Waste Disposal: Utilizing declared weight × carbon emission coefficient × IPCC global warming potential coefficient.

- Greenhouse Gas Emissions from Energy Resource Extraction, Manufacturing, and Processing: Activity data × carbon emission coefficient × IPCC global warming potential coefficient.

In greenhouse gas inventory, Layana employs the uncertainty factors recommended by IPCC to assess the error range of activity data and emission factors, thus calculating the overall emission data uncertainty. The baseline year for this inventory is 2022, and if boundary changes or error corrections exceed 3%, we will reset the baseline year for comparison to enhance the reliability and transparency of the report.

Layana has implemented various reduction strategies such as energy management and improving equipment efficiency, and these measures have started to yield results. This not only demonstrates our responsibility and efforts in environmental management but also elevates the level of our internal control system. Environmental protection measures within our company have been systematically regulated and continuously improved, highlighting our determination to fulfill social responsibility. In the future, we will continue to strive for better carbon reduction performance towards our carbon-neutral goals.

The Genesis of ISO 14064 Greenhouse Gas Inventory

In 1997, the "Kyoto Protocol" mandated contracting parties to implement specific greenhouse gas emission reduction targets. The United Nations Framework Convention on Climate Change (UNFCCC) initiated work on greenhouse gas inventory and, in 1998, established the Inventory Task Force, developing the first version of the Greenhouse Gas Inventory and Reporting Guidelines, the precursor to ISO 14064 standards. ISO first released ISO 14064-1 Greenhouse Gas Inventory and Reporting Standard in 2005, assisting companies in greenhouse gas inventory work. With the adoption of the "Paris Agreement" under the United Nations Climate Change Convention, the standards have been continuously updated and improved. The latest international standard specification is ISO 14064-1:2018, released in 2018.

The Principles of ISO 14064-1 Greenhouse Gas Inventory

These principles ensure the credibility, reliability, and comparability of organizational-level greenhouse gas inventory and reporting.

-

Relevance: The relevance principle requires organizations to identify and report all greenhouse gas emissions relevant to their activities and operations, choosing disclosed items, whether direct or indirect. This includes production processes, energy use, transportation, and various other aspects. By ensuring the inventory content is relevant to the organization's actual situation, the organization can more comprehensively understand its impact on climate change, making the inventory report more reference-worthy.

-

Completeness: Disclose all significant emission sources and scopes, inventorying all possible greenhouse gases to ensure completeness. This helps assess the contribution to climate change more comprehensively, forming more feasible emission reduction strategies.

-

Consistency: Use the same methods for greenhouse gas measurement and reporting across different times and scopes. This helps ensure data comparability, enabling tracking and evaluating changes in emissions trends. It makes it easier for stakeholders to compare environmental performance between different periods.

-

Accuracy: Ensure the accuracy of measurement methods and inventory records. This includes precise measurement and calculation of emission sources and recording the accuracy of relevant data. High data reliability ensures the organization can formulate reasonable emission reduction strategies based on actual circumstances.

- Transparency: Inventory reports should provide clear, understandable, and specific information, enabling stakeholders to understand the inventory process, methods, and results. This helps build trust and makes the inventory report more welcomed by stakeholders.

The Structure of ISO 14064-1 Standard

- Determine Inventory Scope: First, determine the scope of greenhouse gas inventory, covering which emission sources. If there are investments in other companies, carbon emissions need to be calculated based on the equity proportion, usually using the control method. This helps ensure the completeness of the inventory and better assess the overall greenhouse gas situation of the organization.

- Establish Inventory Baseline Year: The main purpose is to establish a performance comparison baseline for greenhouse gas management and evaluate the achievement status of reduction targets. Single-year data, multi-year averages, or rolling averages are typically chosen. The organization can change the baseline year but must explain the reasons for the change. When disclosing category changes, changes in quantification methods, or changes in ownership and control that meet significant thresholds, the baseline year must be recalculated.

- Identify and Assess Emission Sources: Identify and assess emission sources to ensure the accuracy and completeness of greenhouse gas inventory. This includes direct or indirect emission sources, such as purchased electricity, food delivery, customer visits, employee commuting, raw material purchases, consumer use, etc.

- Establish and Maintain Inventory Records: Establish and maintain accurate greenhouse gas inventory records, including inventory methods, data, and calculation processes. This helps verify the process and ensure the credibility of the data.

- Transparency of Inventory Reports: Publicly disclosing greenhouse gas inventory reports ensures data transparency. The inventory report should clearly present the inventory process, data, and results for stakeholders to assess and reference.

▲ January 11, 2024, External Audit for ISO 14064

Conclusion

Just as ancient mariners relied on the stars for navigation, the ISO 14064 standard has outlined for us a future blueprint of resource conservation and steadfastness. We can, in accordance with its guidelines, advance greenhouse gas verification and reduction. The collective efforts of humanity can transform Carbon Emission Label management from a burden into a precious resource. Through the ISO 14064 standard, we learn to cherish our environment better, embarking on the path of sustainable development for our planet.

ISO 50001 Energy Management System

The Definition of ISO 50001 Energy Management System

ISO 50001 is Energy Management System (EnMS in abbreviation). The goal of ISO 50001 EnMS is to reduce the cost of enterprises and improve environmental issues by decreasing energy consumption. In order to solve the impact that comes from the substantial energy consumption and climate change the global, by establishing Energy Management System, enterprises think outside the box of the energy cost on energy performance management to improve the use efficiency of enterprises and to reduce the emission of greenhouse gas for saving the cost of energy consumption of enterprises. Besides, for reducing the various impact on the environment caused by the operation of an enterprise.

The Importance of ISO 50001 Energy Management System

ISO was first released in June 2011. Now the latest version is ISO 50001:2008 EnMS which was released on Dec. 21, 2018.

According to the data in 2016, the top five countries that acquire the most ISO 50001 certificates are Germany, the United Kingdom, Italy, China, and France. Four of these five countries are located in Europe, which means ISO 50001 EnMS in European countries has been a practical action, not a symbolic indicator. As of the end of 2017, 22,870 companies around the world have passed the verification of this standard. Europe gets the highest ratio for passing the verification, and the following is in Asia. More and more companies include ISO 50001 EnMS in their sustainable development strategies, which strengthens the requests to suppliers for adapting to the changes in the energy supply environment. If the rise of awareness is happening, the ISO 50001 EnMS can be developed extensively.

ISO 50001:2018 EnMS's Main Principles

-

ISO 50001 EnMS is already compatible with the existing standard management system of an enterprise. For instance, the company has an ISO 9001 quality management system and an ISO 14001 Environmental Management System which can smooth the process of ISO 50001 implementation.

-

The company uses the PDCA circle to improve its work routine continuously. The principles of the PDCA circle are -

-

Plan: Proceeding the physical examination of the departments and machines in the entire factory. To analyze the distribution situation of energy consumption of the production facility, and to formulate the action plan for energy-saving and carbon reduction as per the needs of each unit. -

Do: Based on the plans for energy-saving and carbon reduction, the actions for each department are to carry out the staff training, and replace old facilities with new ones, etc. -

Check: The duty of a supervisor is to confirm the actual improved situation with each department head and staff together. -

Action: Modify the action plan for energy-saving and carbon reduction anytime to make sure the plans of each department achieve the best outcome. If a problem needs to be addressed, it has to be proposed immediately and then to be executed after the review.

-

ISO 50001 is used to establish, supervise, document, and provide energy reports for predicting greenhouse gas emissions and finding out solutions.

Assist enterprises to optimize energy management and reinforce good management behavior.

-

Evaluate and determine the use of new energy that includes the potential energy, the use of renewable energy, the development of alternative energy, etc.

The Example of Acquiring ISO 50001 Energy Management System

Layana completed the audit of ISO 50001:2018 EnMS in 2019. By making itself an example, Layana implements energy management in the operation of the entire factory and shares it with supplies and clients. Layana’s indicator for energy management is as the following:

Conclusion

Economic growth plays a vital element in a country; however, while pursuing economic development, humans may unconsciously sacrifice the natural environment and ecology. Although Mother Earth does not protest in time, it accumulates over a period of time damage, it eventually leads to counterattacks. For example, the hole in the ozone layer, global warming, and the melting of icebergs at the South Pole and the North Pole.

ISO 50001 EnMS certification helps companies to take sustainability into consideration when pursuing margin profits and sales revenues. In the 21st century, we have to utilize the existing resource effectively which can be passed down the benefits to the next generations.

Article reference source: 22,870 data in 2017/ Top 10 Countries for ISO certificates/ Production & Ecology & Life chart reference to Xie Xhencheng at SGS Taiwan Limited.

ISO 50001-2018 introduction for a new version of energy management system standard.pdf

Environmental and Energy Policies

Since its establishment in 1982, Layana has been dedicated to nurturing high-quality partnerships with suppliers and clients. We strive to provide our employees with a conducive environment for their well-being and ongoing personal growth. In pursuit of sustainable business practices and the establishment of rigorous standards for environmental impact management, we have implemented the ISO 50001 Energy Management System. We hold in high regard the responsible utilization of all forms of energy, actively champion energy-saving initiatives. All colleagues collectively drive the ISO 14064 Greenhouse Gases, taking tangible steps towards energy conservation and fulfilling our obligations as responsible global citizens, thereby laying the foundation for continuous improvement in the future. We hereby commit to and persistently advocate for the following initiatives:

Environmental Policy

- Regulatory Compliance: We ensure that all our production activities strictly adhere to regulatory requirements. Our commitment lies in driving green supply chains and offering environmentally friendly products. Through continuous improvement of our work environment, we aim to achieve the goal of zero occupational accidents.

- Environmental Protection: We prioritize product designs with low toxicity and easy disassembly, conduct thorough carbon footprint assessments, practice resource conservation, industrial waste reduction, pollution prevention, and enhance control over hazardous substances. Our objective is to minimize our environmental impact.

- Resource Optimization: We place great emphasis on personnel education and training, fostering a culture of continuous improvement within our operations. By doing so, we strive for sustainable development and contribute to a greener future.

Energy Policy

- Regulatory Compliance: We provide energy improvement resources and diligently implement energy laws and regulations to ensure compliance at all times.

- Enhancing Energy Efficiency: We actively seek equipment procurement with energy-saving certifications and integrate energy-saving designs and processes into our operations. Our aim is to achieve significant energy savings and meet our targets.

- Inclusive Engagement: We believe in creating an energy-conscious organization where everyone plays a part. Through the establishment of effective energy strategies and the active involvement of all employees, we drive sustainable business practices.

- Continuous Improvement: We consistently strive for betterment by implementing material conservation designs, reducing energy consumption, and optimizing energy usage efficiency.

Green Factory

What is a green factory?

| A green factory refers to a manufacturing facility that prioritizes environmental sustainability in its production processes, products, and infrastructure, surpassing the standards set by traditional factories. In the face of climate change, green factories serve as a vital solution within the industrial sector. The primary objective of a green factory is to demonstrate respect for the environment by diligently working towards reducing carbon emissions, minimizing waste generation, and optimizing energy consumption during the manufacturing of products.

Typically, green factory certification is bestowed by governmental authorities, acknowledging companies that invest in creating eco-friendly facilities that provide a healthy and comfortable working environment for employees, all while reducing their carbon footprint. Accreditation bodies for green factories conduct comprehensive audits encompassing various aspects of the production process. These aspects encompass the efficiency of industrial equipment, energy optimization of cooling and heating systems, waste management and recycling practices, water resource management, sustainability of inputs, carbon emission reduction associated with logistics demands, energy consumption for factory lighting, energy efficiency, and risk mitigation considerations in architectural designs.

The establishment of a green factory necessitates coordination and collective efforts across all internal departments of a company, fostering a shared understanding of the essential principles that drive green manufacturing practices. Active engagement of departments and employees enables the identification of areas with potential inefficiencies and opportunities for improvement, thereby facilitating the development of innovative solutions to enhance factory efficiency while minimizing or eliminating waste. |

How to become a green factory?

|

Becoming a green factory involves meeting two essential criteria:

Only when these two factors are successfully integrated can a factory truly be considered green. In essence, the realization of a green factory requires a dual focus on creating environmentally friendly infrastructure and implementing sustainable production practices. |

The fundamental steps to obtain Green Factory certification are outlined below:

- Set mid-term objectives to transform your factory into an environmentally sustainable facility, either through construction or renovation.

- Develop a comprehensive plan focusing on addressing sustainability issues related to the establishment of green factory infrastructure and production processes.

- Create a roadmap for the future by establishing measurable standards and target completion dates for each stage. For instance, goals may include reducing water loss by 10% following the installation of new equipment, achieving a 20% decrease in energy consumption for a specific process after completion, and completely eliminating the use of highly polluting materials.

- Establish a dedicated team responsible for coordinating and making decisions regarding the implementation of improvement plans across various departments.

- Formulate teams to handle infrastructure planning and clean production planning. Effective communication between these teams is crucial to understanding project requirements and progress.

- Conduct regular meetings to ensure alignment within the company. During these meetings, assess the feasibility of proposed plans, approve or reject their implementation, and analyze the progress and outcomes of previous initiatives.

- Consider necessary permits or approvals before commencing construction and manage them accordingly. Take into account pre-building requirements such as zoning regulations, environmental agreements, seismic and stormwater management, drawings, or projects approved by relevant government agencies or institutions.

- It is highly recommended to engage experienced construction companies and architectural design firms with expertise in constructing environmentally sustainable facilities.

- Identify the environmental requirements that the construction company must adhere to when building a new factory or renovating an existing one. Additionally, conduct periodic audits of the construction work to ensure compliance with these requirements, which may include measures such as preventing the release of dust or pollutants into the atmosphere and implementing waste reduction and recycling practices.

- Once the new factory infrastructure is completed and new equipment is installed or existing equipment is improved, validate the production capabilities within the facility. Make any necessary adjustments until the desired production levels are achieved.

The Impact of Green Factories

When evaluating the impact of constructing green factories, it is crucial to identify the entities affected by this impact.

- The foremost and most significant impact is on the environment. By opting for the construction of green factories instead of more polluting traditional alternatives, not only do we avoid air, water, or environmental pollution, but we also strive to minimize potential damage to the environment, particularly the disruption of animal and plant populations. Furthermore, green factories are designed to ensure responsible usage of local natural resources.

- There is a positive and substantial impact on the health and well-being of employees. The design of green factories takes into account the working environment, including measures such as providing an adequate number of mobile restrooms and reducing workplace carbon emissions. This not only reduces the probability of work-related accidents but also significantly improves the overall working conditions for employees. Moreover, when employees' health and happiness improve, it extends to the well-being of their families.

- The establishment of green factories contributes to the advancement of industrial capabilities in urban areas. Green factories exhibit resilience in the face of future challenges or crises. Additionally, they alleviate the strain on the region's power systems and water resources, as their resource consumption is significantly lower compared to traditional construction practices.

- Green factories have a positive impact on local residents. Apart from integrating corporate social responsibility initiatives aligned with green factory designs, the employment opportunities offered by companies committed to sustainable development without compromising the local ecosystem also increase. Furthermore, by setting examples of businesses dedicated to environmental and human well-being, it fosters a positive influence on future entrepreneurs.

- Obtaining green factory certification not only adds value to the company but also creates value within the production and manufacturing processes. Green factories enhance the company's reputation, provide tax benefits, and reduce production costs, ultimately making the company more competitive and improving its business prospects.

The Challenges and Opportunities of Embracing a Green Factory

Constructing a green factory comes with numerous advantages, but it also presents challenges and risks that not all companies are willing to undertake.

Despite a company's significant efforts to enhance production and incorporate eco-friendly building practices, obtaining certification may not always be feasible. Alternatively, even if certification is eventually achieved, it may require more time and financial resources than initially anticipated. To mitigate such situations, Layana suggests that the decision to establish a green factory should be driven by the company's genuine environmental consciousness, rather than solely being motivated by the ambition to acquire a certificate. The certification serves as a powerful instrument, affirming that the company is making sound decisions and taking meaningful steps towards achieving its objectives.

Furthermore, the requirements, indicators, recommended materials, and production standards necessary for compliance may evolve over time, necessitating future modifications and enhancements. To address this, Layana recommends that companies internally adopt a policy of continuous improvement, surpassing the requirements outlined in certification systems or legal frameworks related to environmental sustainability.

Additionally, the construction of a green factory entails extensive planning, seamless team coordination, resource allocation, and meticulous auditing. Consequently, unwavering commitment is essential, ensuring that the company remains dedicated to these principles over the long term. On one hand, a company opting for a green factory showcases its leadership and forward-thinking approach, thereby bolstering its reputation. On the other hand, official certification as a green factory serves as tangible evidence of the company's unwavering dedication and significant progress. Consequently, such a company cannot be accused of mere "greenwashing," as the green factory certification necessitates a comprehensive evaluation by the supervisory authorities.

Taiwan's Green Factory Certification System

In Taiwan, the Green Factory Certification stands as an advanced standard for recognizing environmentally sustainable buildings. The Industrial Development Bureau of the Ministry of Economic Affairs is responsible for awarding this esteemed certification. The Taiwan Green Factory label is recognized worldwide as a groundbreaking initiative, honoring companies that prioritize clean production practices in their factory designs. These practices encompass energy and water efficiency, waste reduction or elimination, pollution prevention, employee well-being through improved workplace conditions, protection of surrounding ecosystems, and commitment to corporate social responsibility. The Green Factory assessment evaluates whether the factory's building itself meets green building criteria and if its internal production processes adhere to clean production standards.

Layana strives to embody environmental friendliness while adhering to international environmental standards. In addition to integrating natural and green elements into our building structures, we have implemented scalable recycling systems and lush green gardens in our factory space designs. We champion energy-saving and carbon reduction measures by employing energy-efficient lighting and air conditioning systems in our day-to-day operations, along with measures to reduce CO2 emissions within our facilities. Our ultimate goal is to minimize the environmental impact of our factory and production processes, bolster the industry's commitment to sustainability, and achieve carbon neutrality.

LAYANA has obtained the Green Factory Certification and has passed the evaluation of the Cleaner Production System.

|

2022 Taiwan's Green Factory Label Celebrates 10th Anniversary |

Green Factory Certification |

Green Factory Certification |

The History of our Green Building Factory

|

|

|||||||||

April 2014Start of design phase Obtained building permit |

September 2015Inauguration Ceremony |

July 2016Coronation Ceremony |

November 2017Obtained Green Building Candidate Certificate |

February 2018Factory Registration Certificate |

August 2019Obtained Gold-Level Green Building Certificate |

September 2021Obtained Carbon Footprint Label |

January 20221. Obtained Cleaner Production System Certificate 2. Obtained Green Factory Mark |

2024Obtained ISO 14064-1 Greenhouse Gas Certification |

2025Renewal of Cleaner Production System Certificate & Green Factory Mark |

Conclusion

The Green Factory Certification Label is not only a recognition of the company's team members, but also a way to give back to the natural environment on which humanity depends. The process of achieving a green factory, from Green Building and Clean Production to obtaining the Green Factory Certification, involves guidance, implementation, adjustments, audits, and certifications at each stage. The original intention of caring for the environment will continuously evolve through the interplay of ideals and reality. The key to maintaining the ideal of a green factory is to adhere to the principle of minimizing environmental impact and making solid progress step by step.

Green Building

What Is Green Building?

Green buildings have different names and definitions in each country. The earliest concept of green building was in the 1960s, which was about the low environmental impact represented by "environmental symbiosis housing" from Japan and the "ecological building" from the United States. Until 1990, the United Kingdom issued the world's first standard of green building. The purpose was to implement the norm of "use the least earth's resources and create the least waste" in the life cycle of a building, from renovation, planning, construction, and operation to demolition. Each country will create its green building standards according to its geographical and climatic conditions.

The Green Building Certification System

In 1999, the Taiwanese government established the Green Building Certification System, known as EEWH, which came right after the LEED in the US. The EEWH includes four main aspects - Ecology, energy saving, waste reduction, and health. The green building works for all the project types, which have four options: basic, residential, Eco-community, industrial, and building renovation.

The Green Building Regulations and Enforcement Rules

According to the Green Building Assessment Manual – the green building assessment has been divided into nine categories.

Ecology

Ecology can be evaluated in three aspects -

|

1. |

Biodiversity: This assesses the area of biological habitats and activities in natural areas such as vegetation, soils, light pollution, and biological movement barriers. This metric only applies to the project if more than one hectare. |

| 2. | The level of the greenery: The difference between this index and the ecological diversity index is in quantity and quality. The amount of greening is calculated according to the type of planting, and the soil depth is required to be 0.3~3.5m. Floristics can be divided into ecological multistratal, arbor, shrubs, perennial vines, flowerbeds, meadows and old trees, etc. |

| 3. | Soil moisture conservation: It refers to water content capability, as well as the storage and infiltration of rainwater. The higher the water retention, the better to help the microbial activity in the soil. It can improve the organic quality of soil and cultivate plants. The water retention can be calculated through the area of green space and the volume of garden soil, the paving area of permeable bricks, and other special water retention designs. |

Energy Saving

4. Energy saving can be evaluated in three following aspects-

A. The shell of the building: The building design should include ventilation, and roof insulation of heat to avoid the need for air-conditioning. Using energy-saving glass can help to reduce indoor temperature, etc.

B. Air-conditioning: High-efficiency air-conditioning system, energy-saving, CO2 detection, etc.

C. Lighting: To maintain daylight, all indoors should have sufficient windows. By using energy-saving lamps with automatic dimming, a control system, and chosen high-brightness colors to improve the lighting level, etc.

Waste Reduction

5. CO2 reduction: It is to review the CO2 content that includes bricks, tiles, rebar, and glass in buildings. CO2 emissions will be scored based on 4 structures: structure rationalization, lightweight construction, durability, and recycled materials. For example, the building should be as regular and square as possible; the use light rebar and the use of lightweight material for partition walls. Additionally, seismic resistance and the use of recycled materials should also be considered.

6. Waste reduction: It is aimed at comprehensive pollution control in the process of building construction. Among them, construction pollution sources include construction waste, solid waste from demolition waste, engineering balance earthwork, and construction air pollution. Suggested solutions include installing dust-proof nets, and dust-proof plastic cloths, setting up wastewater pollution treatment systems and using recycled building materials.

Health

7. Indoor environment: This index appeals to low pollution, low fugitive, and recyclable building materials design to evaluate whether it is friendly to human health and the global environment. This can reduce the harm of carcinogens to the human body and the burden on the earth. The indoor environment is divided into four categories: light environment, sound environment, ventilation, and indoor building materials.

8. Water resources: According to the geographical environment and climatic conditions of Taiwan, take the advantage of more than 2,500 mm of rainfall annually that makes good use of water resources. Recycling water resources can help to reduce the cost of development and to avoid the loss of water. Water resources assessment such as products with water-saving labels-faucets, toilets, public hydrants; planning rainwater recovery systems to calculate water storage levels, etc.

9. Improvement of sewage and garbage: Mainly to evaluate whether the sewage and garbage treatment system is implemented and should be strengthened. For example, all domestic miscellaneous water discharge systems should be connected to sewage pipes and treatment facilities, sufficient space for garbage placement and transportation, geotechnical installations for recycling, food waste collection systems, etc.

The Green Building Rating System

According to the green building assessment, the score range has been divided into:

- Diamond

- Gold

- Silver

- Bronze

- Passed

How Did We Design the Green Building?

Layana was certified with Gold-level Green Building (EEWH-Gold) in 2018, in Taiwan. The essence is a manufacturing factory, so the application category is a green building factory. In the early stage of plant planning, it developed along the four principles of energy saving, greening, health, and waste reduction. Among them are the targets for significant improvement:

- The level of the greenery – through gardens, planting, green space, etc., the total green area is 4,780 square meters, and the greening ratio is 37.8%

- Soil Moisture Conservation – using water permeable pavement, the area, and the volume of the gardening area to calculate the water retention. ZQi=328.37

- Energy saving from the shell of the architecture – widely added windowsills to avoid direct sunlight, plus inlaid the heat insulation materials into the rooftop, can reduce the heat transfer rate. Layana’s headquarter is on average rate.

- Energy-efficient air conditioning – chose the right air conditioning system which includes air purification, and energy recovery ventilation (ERV) to comply with the rules of energy saving.

- Water Saving – Layana’s headquarter used a raft foundation to create the rainwater recycling system. Rainwater is stored in the basement which can save 7,900 tons of water every year. Please find the further story here.

- CO2 reduction – Layana executes recycling, regular cleaning, and minimizing the waste of construction can dwindle the carbon emission.

The Benefits of the Green Building

- Energy Saving – first of all, the construction cost may be higher than the average cost of a building project. However, in the long term, the energy cost can be saved a lot by complying with the regulations of green buildings.

- Low Maintenance Cost – if the architecture planning is well considered before the construction start, then its following maintenance for green buildings can be easier than for non-green buildings. For example,

- Raised the quality of the working environment – creating a healthy, comfortable, and sustainable indoor environment can improve human beings in both physical and mental ways. CO2 detectors can monitor indoor CO2 density.

The Effects of Having Green Buildings

It changed the values of the land and properties. For example, in Taiwan, according to the level of green building, the living area, and the original property price, there is a green premium between green buildings and non-green buildings, and it will last over time. (2017) In short word, green buildings can raise the value of the property itself, and non-green-buildings decrease at the same time.

The Guidelines for Green Building Projects

- Understand the types of green building projects – to know the project direction whether is new building construction or an existing building renovation, then to see which category suits the best - residential, commercial/industrial, eco-community, or building renovation.

- Set up a target of Green Building Certification – according to the rating system, it would suggest that design a building architecture in according to the nine categories of green building. If the project is a renovation, then an analysis of the strengths and weaknesses of achieving green building certification is a need. Making the most efforts in the right place will be the effective way to acquire the certificate.

- Create a task force – the team should be multidisciplinary, which includes quality, accounting, facility management, and procurement to go through the project. The team should be competent and actively involved in the process.

- Find the right person – the architect shares the same values with the owner and is willing to make the project happen.

- Choose suppliers wisely and carefully – suppliers include contractors and hardware systems. It would be beneficial to understand the capability of contractors if the project manager can visit some physical examples of contractors.

- Monitor the quality of the construction continuously – to maintain the quality of the structure, the task force can help to validate materials, generators, air conditioning, and so on. External audits are required during the construction period.

- Execute the acceptance of work – the quality of the construction should be consistent throughout the project. Every phase should have inspections or acceptance of work to get approvals from external audits.

- Execute the contract – as a project leader, an incentive can encourage constructors to finish the work before the deadline with the same quality. If constructors need to prepay expenses, then allow it within capable range.

- Execute the facility test – use the actions to validate the finished work. For example, the production can produce a batch of products successfully.

The Summary

The definition of green architecture nowadays extends beyond just the appearance of buildings; it also encompasses the importance of sustainable design in terms of building materials and construction methods. These practices all aim to reduce environmental impact and achieve the goals of "environmental prosperity" and "health and wellbeing" through energy-efficient, low-carbon, and sustainable operational approaches. The current development of green architecture in Taiwan has achieved some success, and in addition to green building certification, there are other sustainable initiatives that can be implemented, such as energy management systems and sustainable manufacturing in factories. For this precious planet, businesses should continuously strive to protect and conserve, without ceasing.

Cleaner Production

What Is the Cleaner Production?

Recently, the urgent need to reduce the industry's carbon footprint led to the term cleaner production being on everyone's lips today. However, only a few companies integrate a comprehensive strategy to achieve cleaner production. Cleaner production refers to new procedures and technological solutions enabling new practices at all industrial production levels for environmentally sustainable manufacturing. Reducing or eliminating potentially harmful components, minimizing the emission of waste of any kind to the environment, and achieving the product by reducing the amount of energy, hydrological resources, or the needed input materials, will contribute to cleaner production within an environmentally sustainable company.

The Characteristics of the Cleaner Production

- Renew Equipment – Installing more efficient equipment to use a smaller amount of material or inputs and require less electricity, water, or other resource consumption.

- Improvements in the usage of material – Implement improvements or new technologies to take more advantage of the available materials, avoid waste, or replace polluting materials.

- Design innovation – Reduce the amount of material needed or design more durable products over time.

- Improvements in waste treatment – Reuse and recycle all excess material and treat, reduce, and even eliminate waste before released into the environment.

- The Substitution of Packaging and Labeling – Decrease the amount of plastic and use materials that are recycled or obtained from cleaner production.

- Source materials locally – Use inputs from local manufacturers and optimize the distribution chain by reducing the mileage needed for inputs to reach the factory and for manufactured products to reach the end customer.

- Improvements in production and maintenance tasks – Prevent future potential environmental damage.

Improvements in facilities – Protect the health of employees and reduce energy, water, or any other resource consumption.

Cleaner production is a comprehensive concept that integrates all company departments. For the correct implementation of a strategy for cleaner production, it is necessary to coordinate and involve all the teams and all the departments to find possible failures, inefficiencies, or opportunities, propose and analyze potential improvements, and implement and measure them. Furthermore, when designing the corporative policy regarding environmental sustainability, it is critical to emphasize the continued implementation of cleaner production plans. Continuous improvement is how a business can stay competitive.

The Benefits of the Cleaner Production

The benefits of applying a cleaner production program are multiple and can be classified into two groups: social & environmental benefits and corporate benefits.

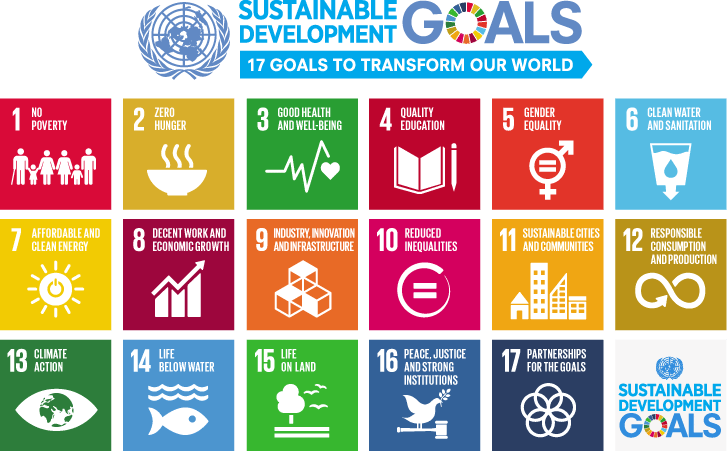

On the one hand, as mentioned in previous lines, companies continuously implementing an improvement program to achieve cleaner production proactively contribute to the collective achievement of a large part of the United Nations Department of Economic and Social Affairs' sustainable development goals. Through the implementation of cleaner production, we can contribute to the following achievements (UN official goal numbering in brackets):

- Good health and well-being (3) – A cleaner production site will be a much more pleasant and healthy environment (both physically and mentally) for employees. We can better prevent accidents at work, ensure that workers are healthy, and thus help relieve public health services.

- Clean water and sanitation (6) – Rainwater collection systems will help reduce water consumption, reducing demand and increasing clean water availability for those in need. Besides, for industrial water purification systems, a decent water purification and drainage system will ensure that the water after its industrial use can be recycled and reused.

- Affordable and clean energy (7) – By improving the energy efficiency of production equipment, the industrial demand for energy decreases, which will contribute to an energy price drop for households. In addition, increasing the demand for clean energy by incorporating it into industrial uses will boost renewable energy development, improving its technology and competitiveness.

- Decent work and economic growth (8) – Implementing a cleaner production program will help to improve the local business fabric resilience, preparing companies to be more competitive in the future and generating higher quality employment.

- Industry, innovation, and infrastructure (9) – The success of a cleaner production program is due in part to technological solutions or innovations in processes that make it possible to achieve more efficient use of available resources or reduce waste. The continuous search for these solutions will contribute to the development of collective ingenuity and the workers' preparation.

- Sustainable cities and communities (11) – A cleaner production is an inevitable step in turning a traditional factory into a green factory. Green factories help to create more sustainable, safe, and resilient cities.

- Responsible consumption and production (12) – Cleaner production is closely related to eco-efficiency since one of the ultimate goals is to reduce the carbon footprint when producing new goods. It is necessary to know how to convey to the customer the benefits of a cleaner production system so as not only to promote responsible production but also responsible consumption.

- Climate action (13), life below water (14) and life on land (15) – According to the European Environment Agency, industrial processes account for 9.1% of total greenhouse gas emissions, without counting the emissions emitted by the generation of energy necessary to feed factories. It is vitally important to reduce the carbon footprint when producing goods because the environmental consequences of rising temperatures can seriously jeopardize the fragile balance of ecosystems needed for the proper development of human and animal life. Melting ice from the polar caps, floods, droughts, devastating storms, or plagues are just some of the terrible consequences if the earth's average temperature keeps rising.

On the other hand, at a corporate level, the implementation of a cleaner production system has numerous advantages:

- Energy savings – Even though sometimes the installation of more energy-efficient equipment means higher installation or implementation costs, it will save on electricity bills in the long run.

- Water saving – Using water recycling systems means significant annual savings in water bills, apart from making the company more resilient to potential supply problems.

- Increase employees' efficiency – A clean environment, with clean air and adapted room temperature, stabilize employees’ health and work efficiency. In addition, many of the plans included in cleaner production programs bring measures that reduce the possibility of accidents at work.

- Improved company image – A company will have a better reputation and more prestige when it is concerned with reducing its carbon footprint and cares about taking care of its employees and members of the community where the company is based. It is also synonymous with transparency and commitment.

- Improved profit margins – Making better use of the material at the production time and reducing the amount of waste processed before emitting it into the environment will increase profit margins.

The Obstacles to the Implementation of the Cleaner Production

Although cleaner production systems bring numerous benefits overall, there are also concerns that lead some businesses to not prioritize clean production plans and instead postpone their implementation until national regulations compel them to make improvements. Some of these concerns include:

- Lack of funding for improvements - Implementing improvements sometimes requires a financial investment. In such cases, the motivation for investment and the potential long-term benefits of the improvements need to be carefully considered.

- Lack of cohesion - Implementing a clean production plan requires the full participation of all departments. It can be challenging to coordinate tasks and communicate effectively across different departments during the process.

- Lack of technological resources - Not all company departments can apply clean production system solutions at the same pace. However, companies should approach clean production with the same determination and commitment.

- Lack of environmental awareness - Not all companies consider environmental conservation as a core value and a guiding objective. Layana, on the other hand, not only recognizes sustainable development as an imperative goal but also believes that continuous improvement will consistently reduce carbon footprint and protect the environment.

The Exampple of Implementing the Cleaner Production

For instance, Layana's implementation of cleaner production encompasses a series of plans and measures categorized into three main areas: production and manufacturing, environmental design, and green management and social responsibility. These three categories not only harness the collective efforts of various departments but also demonstrate innovation in seeking solutions, which serves as the fourth criterion for evaluation. As a result, in 2022, Layana was awarded the Clean Production System Assessment Certificate. This certification validates the company's commitment to enhancing ecological efficiency and product yield while diligently reducing waste and minimizing adverse impacts on the environment and human health.

(1) Production and Manufacturing

This plan consolidates all the improvement measures implemented at Layana to reduce energy consumption, lower production costs, and enhance the working environment. Within these improvement measures, the following projects are included:

Energy Saving

- Implementation of automated warehousing: This measure reduces energy consumption and the emission of gases and other pollutants (as we require fewer warehouse equipment and space). Furthermore, compared to traditional warehouses, the installation of automated warehousing alleviates physical burdens on employees and reduces the probability of industrial safety accidents.

- Installation of LED lighting throughout the entire factory: Replacing traditional light tubes with energy-efficient LED lights not only contributes to energy savings but also enhances illumination.

- Deployment of heat recovery systems: By installing insulation materials in various factory equipment and heat recovery systems, we reduce energy consumption and maintain a conducive temperature within the factory.

- Adoption of alternative molds for material conservation: Through the use of substitute molds, our technical team significantly reduces material waste and manufacturing costs.

Investment in variable frequency air compressors: By phasing out fixed-frequency air compressors and adopting variable frequency ones, we greatly contribute to substantial electricity savings and reduced energy consumption.

Water Conservation

This program comprises two primary objectives: the reduction of water loss and the establishment of a system for rainwater collection.

- By installing sediment cooling towers to replace traditional water towers, we can minimize water loss (evaporation and splashing losses) and decrease water and energy consumption as well as production costs.

- The implementation of a rainwater harvesting system facilitates significant water conservation. Additionally, it equips Layana with the capability to respond to natural disasters, ensuring acute water shortages can be alleviated in the event of water supply issues such as droughts or malfunctions.

(2) Environmental Design

Environmental design refers to the innovative approach of focusing on the impacts on human health, chemicals, and the environment and economy during the design and manufacturing of commercial products and processes, rather than being solely driven by regulatory inducements. For example, all the improvement measures implemented at Layana serve not only to enhance products but also to improve employees' working conditions and the environment, while contributing to environmental protection:

- Reduction of plastic usage: Substituting plastic materials used in product packaging with alternatives such as recyclable paper and biodegradable materials.

- Incorporation of carbon footprint labels in Naya's products: Examining the carbon emissions from raw material production to the manufacturing and transportation processes, providing transparency for consumers to choose low-carbon products.

(3) Green Management and Social Responsibility

- Layana engages in various sustainable activities across different domains to contribute to the welfare of society, employees, and surrounding communities. Regular seminars on public welfare and environmental protection are organized by Layana. Furthermore, through the sponsorship of films screened at the 4K3D Dolby Cinema, we promote environmental awareness and highlight the impact of climate change on the natural environment, advocating for a low-carbon/low-energy lifestyle.

- Layana also believes in creating a green working environment to enhance employee health and safety, and encourages a green movement where everyone contributes to environmental conservation. Within the factory, Layana's colleagues utilize eco-friendly utensils, practice paperless office operations, and continuously recycle stationery materials.

Taiwan's Cleaner Production Assessment System

In alignment with the international environmental trends, the Taiwanese government encourages energy conservation and carbon reduction in our country's industries. In 2012, they established the Green Factory Labeling System. The qualification for the Green Factory Label requires compliance with both hardware and software aspects of green specifications. On the hardware side, the factory buildings must obtain the Ministry of the Interior's Green Building Label. On the software side, production and operational management must pass the Industrial Development Bureau's Clean Production Assessment. The Clean Production Assessment System is one of the qualifications for the Green Factory Label, and it is divided into the "General Industry Clean Production Assessment System" and the "Specific Industry Clean Production Assessment System."

Layana's factory falls under the category of the General Industry Clean Production Assessment System, and it successfully passed the Clean Production Assessment System in 2022.

Summary

The implementation of cleaner production enables factories to meticulously scrutinize the possibilities of waste reduction, recycling feasibility, and opportunities for energy conservation and carbon emission reduction within the working environment. This not only allows enterprises to minimize their environmental impact during the manufacturing process but also empowers each individual engaged in cleaner production to contribute to tangible, environmentally conscious actions.

Since 2016, through the collective efforts of all departments and employees at Layana, we have steadily achieved significant milestones in the Green Building and obtained the Clean Production System Assessment, making us the pioneering green factory in Changhua County. By embracing cleaner production, Layana has transformed itself into a more comprehensive and environmentally sustainable enterprise, encompassing aspects ranging from building structures to implementing office stationery recycling. Moving forward, we shall further endeavor to reduce our carbon footprint in accordance with current manufacturing emissions. After all, there can never be too many benevolent actions that humanity can undertake for the betterment of the environment.

Carbon Emission Label

What Is Carbon Emission Label?

The term "carbon emission label" refers to the calculation of direct or indirect greenhouse gas emissions generated throughout the entire life cycle of a product, including raw material acquisition, manufacturing, processing, transportation, distribution, consumer use, and end-of-life disposal. This label, also known as "carbon label" or "carbon footprint label", quantifies the environmental impact and is affixed to the product.

The Development of Carbon Emission Label

|

The evolution of the carbon emission label began in 2001, with the concept emerging as a tangible symbol derived from the carbon footprint. The Carbon Trust, established by the UK government, introduced the world's first global carbon footprint label in 2007, aiming to heighten local manufacturers' awareness of global warming. The term "carbon footprint" encompasses the entirety of an activity or product life cycle. The existence of the carbon footprint label aims to display the product's carbon dioxide emissions (g) directly on the product, allowing consumers to make informed choices based on lower carbon footprint options. As of now, there is no globally unified product carbon footprint label; it has been introduced in various countries, including the UK, Taiwan, France, South Korea, Canada, Japan, and North America. |

International regulations related to carbon emission labels include ISO 14067 for product carbon footprints and PAS 2050 for greenhouse gas emissions assessment of goods and services throughout their life cycle. The differences lie in the organizing bodies and the scope of carbon footprint calculations:

- ISO 14067 for product carbon footprints is developed by the International Organization for Standardization (ISO), while PAS 2050 for goods and services life cycle greenhouse gas emissions assessment is jointly published by the British Standards Institution (BSI), Carbon Trust, and the UK Department for Environment, Food & Rural Affairs.

- ISO 14067's carbon emission calculation encompasses the entire process from raw material production, manufacturing, transportation to sales, use, and recycling, providing a comprehensive and extensive scope. On the other hand, PAS 2050 focuses only on the process from raw material acquisition to production completion, excluding processes like transportation, consumer use, and recycling.

“Cool” the Earth—The Carbon Emission Label in Taiwan

|

Taiwan introduced the Carbon Emission Label system in 2010, aiming to enhance the competitiveness of low-carbon products in domestic and international markets. The meaning of the Taiwan Carbon Emission Label includes:

|

|

In addition to encouraging manufacturers to assess product carbon emissions and apply for carbon footprint labels, Taiwan's Ministry of Environment introduced the "Reduction Carbon Footprint Label," requiring certified manufacturers to reduce their product's carbon footprint by 3% or more within the label's validity period. Once the requirement is met and verified by the ministry, the product receives the reduction carbon label. Products with this label are referred to as "green products," giving them priority in green procurement and consumer choices. The meaning of the reduction carbon label includes:

|

The Example of Applying for a Carbon Emission Label

The Layana tableware brand "Layana Cutlery," established in 2003, utilizes core technologies such as sheet metal stamping and insert molding to design environmentally friendly utensils suitable for Eastern use. The carbon emission labels for Layana Cutlery's products, specifically the spoon and chopsticks obtained in 2017 and 2021, provide transparent information for consumers to choose low-carbon products. In 2019, Layana' factory received ISO 50001 Energy Management System certification, thoroughly examining the factory's electricity usage. In 2022, the factory underwent the Cleaner Production Assessment System, implementing changes for energy conservation and carbon reduction.

Layana, centered around the reusable cutlery brand, adheres to ESG principles and strives to transform into a manufacturer of low-carbon products that are most sustainable for the environment and do not impact human health. Short, medium, and long-term goals are set as follows.

- Short-term goal: Continuously increase the number of products with carbon footprint labels and provide consumers with more information on product carbon emissions, such as dual-section chopsticks.

- Medium-term goal: Reduce unnecessary use of raw materials and switch to environmentally friendly materials to further reduce carbon emissions, for example, precious chopsticks.

- Long-term goal: Achieve carbon neutrality for products and offset the original carbon emissions in an appropriate manner.

Future Trends of Carbon Emssion Labels

Since the signing of the Paris Agreement by 197 countries in 2015, aiming to achieve net-zero carbon emissions by 2050, the European Union has prepared in advance with the Carbon Border Adjustment Mechanism (CBAM). This mechanism requires global traders exporting to EU countries to declare product carbon emissions and purchase "CBAM certificates." The concept of inspecting carbon emissions has evolved from a regional focus to trade agreements between nations and continents.

Conclusion

Since the introduction of the carbon footprint in the 1990s, the tangible labeling of carbon footprints has encouraged manufacturers to independently assess product carbon emissions. The calculation of carbon footprints has evolved to inspecting the carbon emissions of organizations and enterprises. If every company, product, and individual can be aware of and actively reduce their carbon footprint, the Earth can respond favorably to humanity and all living beings. After all, our actions today will determine the fate of the future. How about you? What kind of future do you want to leave for yourself and your loved ones..?

Commercial Rainwater Collection System

What Is A Commercial Rainwater Collection System?

The commercial rainwater collection system can also be called rainwater harvesting system. That is, rainwater is accumulated on-site for other purposes without losing rainwater. The commercial rainwater collection process can be completed according to five steps: collection, storage, filtration, storage, and utilization.

The Applicable Scope of a Commercial Rainwater Collection System

Commercial rainwater collection systems can installed in various places such as airports, stadiums, factories, communities, agricultural irrigation, etc.

The Main Process In a Commercial Recovery Collection System

- Collect rainwater

There are two ways to collect rainwater: one is pulling the tube from the eaves or the top floor ground. The other is collecting from the ground surface. There are different ways of collecting rainwater according to different methods. - Store Rainwater

Rainwater will pass through pipelines into any form that can store; for example, water tanks. - Filtration

This process is to remove impurities, and sediment, and even disinfects, which turns the rainwater into clean water that is ready to use. - Store Cleaned Water

The filtered and purified water is stored respectively in other water pools. - Application

The purified water can either support groundwater or be used for various purposes: plant irrigation, toilet flushing, floor washing, etc.

The Application of Rainwater

- Gather into public groundwater

- Greening environment: planting irrigation, ecological pool

- Domestic use: toilet flushing or floor mopping

- Reduce the impacts of emergencies or natural disasters: water restrictions, droughts, fires, etc.

- Non-drinkable water sources - other industrial uses or agricultural irrigation.

The Benefits of Utilizing a Commercial Rainwater Collection System