The 2024 Sixth Sigma Project Presentation was held on January 19th with a total of eight presenters, one of whom was promoted to Layana's Black Belt and three of them were first time presenters as Layana's Green Belts.

Six Sigma, a management methodology and quality management system, endeavors to augment the quality and efficacy of products or services by minimizing variability. This methodology typically employs two principal approaches: DMAIC and DMADV. One notable project this year marked Layana's inaugural venture into the DMADV Six Sigma design methodology, distinguishing it from the more prevalent DMAIC method commonly employed in factory manufacturing:

DMAIC -

- Define: Clearly articulate the problem, objectives, and scope. Ensure a cohesive understanding among all team members and establish objectives.

-

Measure: Collect data concerning the current process, determining baseline performance. This phase aids in quantifying the severity of the problem.

-

Analyze: Thoroughly analyze data to identify the root causes of the problem. Utilize statistical tools and techniques to identify potential influencing factors.

-

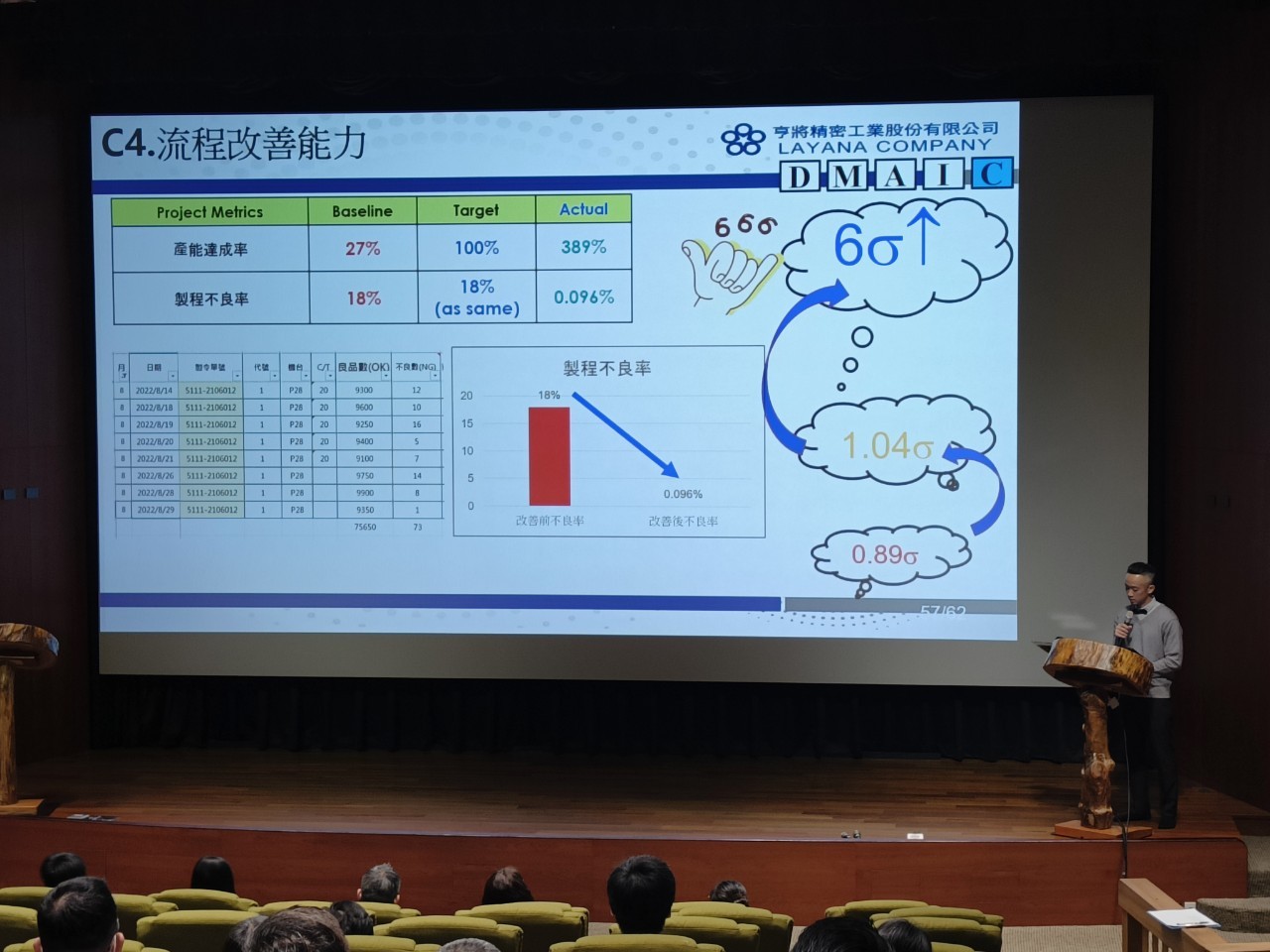

Improve: Based on the analysis, formulate and implement improvement plans. This may include process optimization, equipment adjustments, etc., to attain higher levels of quality.

-

Control: Ensure the sustainability of improvement measures. Formulate control plans, monitor the performance of the new process to ensure its continued operation at the target level.

DMADV -

- Define: Determine the goals and customer requirements for the product or service. Clearly outline the project scope and objectives.

-

Measure: Collect and analyze data about the existing process and product to establish performance benchmarks.

-

Analyze: Determine the root causes of the problem by analyzing data, providing a foundation for the design phase.

-

Design: Develop a new product or service design based on previous analysis. This includes engineering design, process design, etc.

-

Verify: Ensure that the new design meets customer requirements and achieves the expected performance level through testing and evaluation.

In summary, DMAIC is primarily used for optimizing and improving existing processes, while DMADV is applicable to the development of new products or services. Both methodologies emphasize understanding customer requirements and focus on data and statistical analysis to achieve continuous quality improvement. The presenters this year covered diverse topics such as CNC machining, production capacity, brand management, online marketing, and so on. Layana aims for these presentations to serve as an opportunity for individuals to enhance their problem-solving and analytical abilities, plus their experiences can be well-documented with knowledge managment.