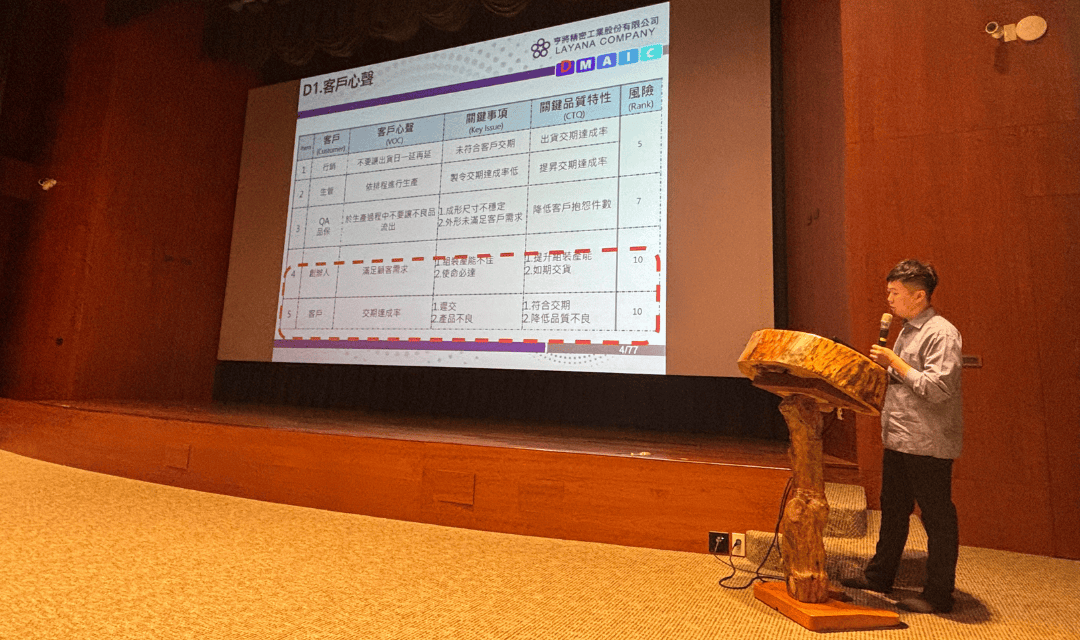

To further embed a culture of continuous improvement and strengthen operational competitiveness, Layana held its 19th Six Sigma Project Presentation on December 24. Continuing Layana’s long-standing commitment to process quality and data-driven management, four project leaders applied the DMAIC (Define, Measure, Analyze, Improve, Control) methodology to deliver systematic improvements and share measurable results across key operational areas.

This year’s Six Sigma initiatives addressed a wide range of strategic topics, including improvements in product flatness quality, capacity optimization, operational efficiency enhancement, and revenue growth. Each project was grounded in data analysis and executed through cross-functional collaboration, enabling teams to identify root causes and implement quantifiable, sustainable improvement solutions—demonstrating the practical depth and value of Six Sigma methodologies.

Through this annual Six Sigma presentation, the company not only reviews optimization outcomes but also continues to cultivate employees’ capabilities in scientific and structured problem-solving, embedding continuous improvement into daily management practices. Colleagues preparing to lead future Six Sigma projects were also invited to participate and learn. Looking ahead, Layana will continue to leverage Six Sigma as a core management tool to enhance product quality, improve operational performance, and create greater value for customers and partners, steadily advancing toward sustainable growth.